Understanding a dual capacitor wiring diagram is crucial for anyone working with single-phase AC motors, particularly in applications like air conditioners, fans, and pumps. A dual capacitor wiring diagram provides a clear visual guide to how these essential components are connected to ensure proper motor operation. These diagrams are not just for electricians; they are invaluable for DIY enthusiasts and technicians alike.

What is a Dual Capacitor Wiring Diagram and How It Works

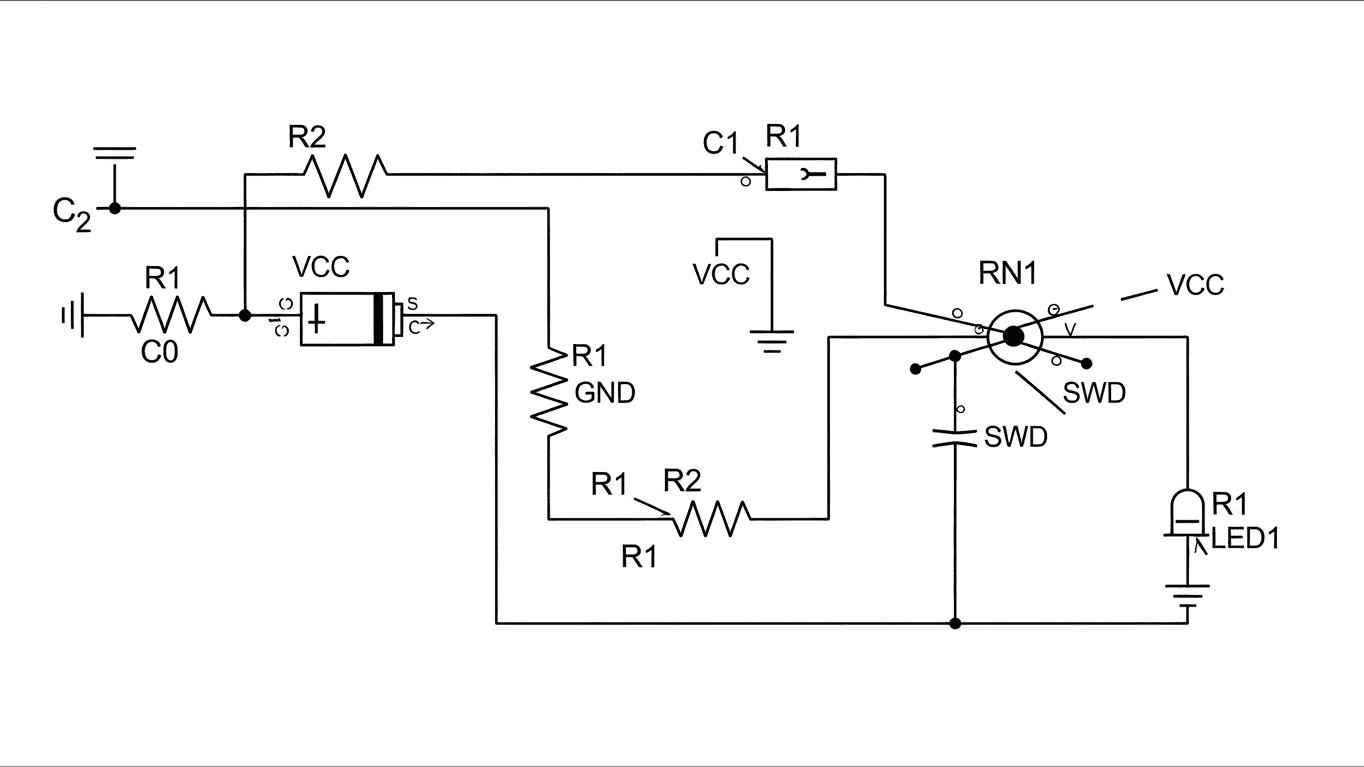

A dual capacitor wiring diagram illustrates the connections for a single component that houses two separate capacitors within one casing. These are typically used in applications where a motor needs both start and run capacitance to achieve optimal performance. The start winding capacitor provides a high surge of current to get the motor spinning, while the run winding capacitor helps maintain efficient operation once the motor is up to speed. Properly wiring a dual capacitor is paramount to preventing motor damage and ensuring reliable operation.

- Start Capacitor: Engaged only during startup.

- Run Capacitor: Continuously active during motor operation.

The diagram will show distinct terminals for each capacitor. For instance, one common setup involves a "C" terminal (common), an "S" terminal (start), and an "R" terminal (run). The wiring will connect the common terminal to the motor's common winding. The start terminal will be wired through a start relay or centrifugal switch to the start winding, and the run terminal will be directly connected to the run winding. This arrangement ensures the start capacitor is disconnected after the motor reaches a certain speed, leaving the run capacitor to perform its role.

Here's a simplified breakdown of typical connections:

| Terminal | Connected To |

|---|---|

| C (Common) | Motor Common Winding |

| S (Start) | Start Winding (via start relay/switch) |

| R (Run) | Run Winding |

When faced with a dual capacitor wiring diagram, pay close attention to the terminal markings and the specific components shown, such as relays and switches. Incorrect connections can lead to the motor not starting, overheating, or premature failure. Always refer to the specific diagram provided with your equipment or consult a qualified professional if you are unsure.

To ensure you have the correct information for your specific project, please refer to the detailed diagrams provided in the resource materials associated with your equipment.