Understanding an E Stop wiring diagram is fundamental for anyone involved in industrial machinery, automation, or even complex DIY projects. This diagram serves as the blueprint for installing and maintaining emergency stop buttons, a critical safety feature designed to quickly halt operations in dangerous situations. A well-understood E Stop wiring diagram ensures that these vital safety circuits function as intended, protecting personnel and equipment.

The Heart of Safety: Understanding E Stop Wiring Diagrams

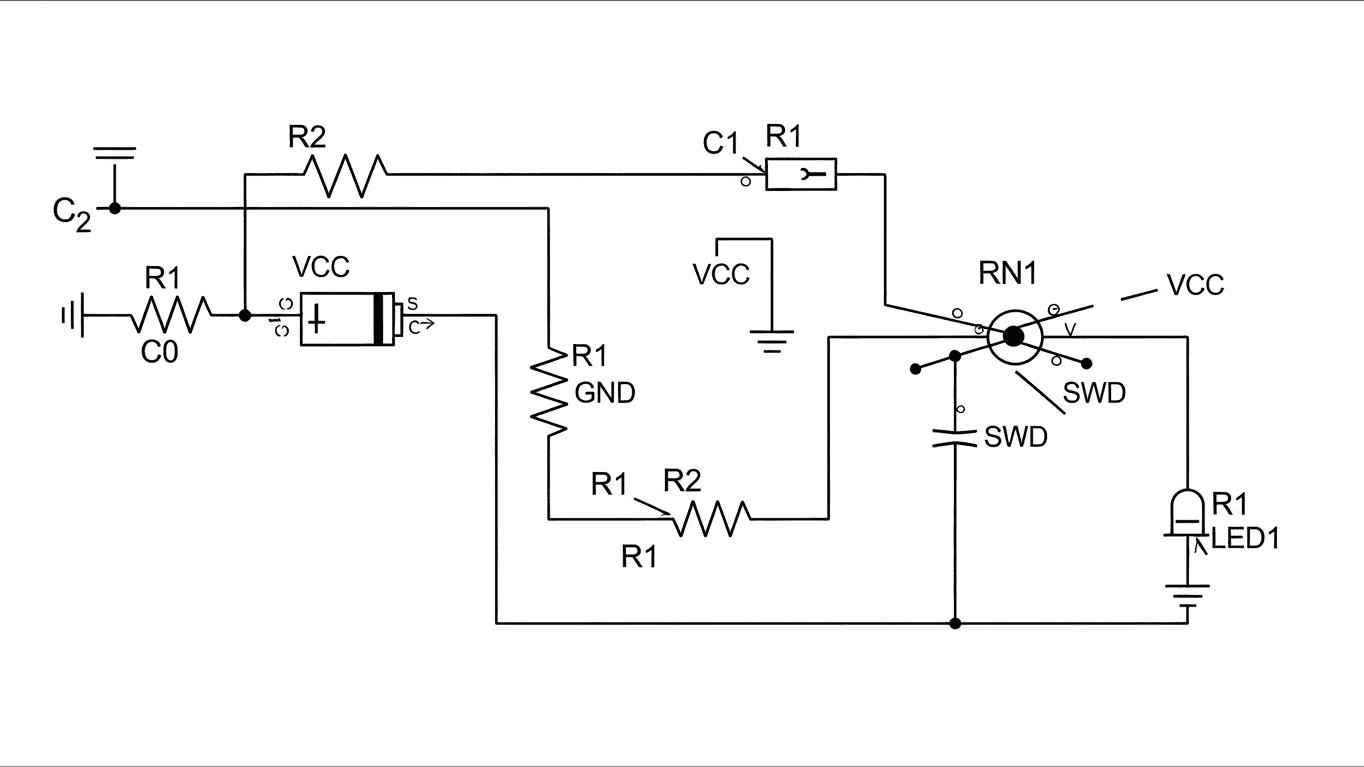

An E stop wiring diagram is essentially a schematic that illustrates how an emergency stop button is connected within a control system. Its primary purpose is to provide a clear visual representation of the electrical pathways involved in the emergency stop circuit. This diagram is not just a technical drawing; it's a critical document that guides the installation, troubleshooting, and maintenance of emergency stop systems. Without a proper E stop wiring diagram, the effectiveness of these life-saving devices can be compromised. The importance of a correctly wired E stop cannot be overstated , as it's often the last line of defense against accidents.

These diagrams are used in a variety of contexts, from large manufacturing plants to smaller workshops. They detail the type of emergency stop button used (e.g., latching, momentary), the type of safety contactors or relays involved, and how these components interface with the main power supply and control logic. Typically, an E stop wiring diagram will show:

- The emergency stop button itself, often represented by a specific symbol.

- The wiring connecting the button to the safety relay or control system.

- The safety relay's internal contacts, which are designed to open or close based on the button's state.

- How the safety relay's contacts interrupt the power to the machine's motor or actuators.

The way an E stop wiring diagram is interpreted can also vary slightly depending on the complexity of the machinery and the specific safety standards being followed. For instance, some diagrams may depict:

- Single-channel emergency stop circuits (less common and often not compliant with newer safety standards).

- Dual-channel emergency stop circuits, which offer redundancy for enhanced safety.

- Integration with other safety devices like light curtains or safety mats.

Here's a simplified look at common components and their connections:

| Component | Function in E Stop Circuit |

|---|---|

| E Stop Button | Initiates the stop signal when pressed. Typically breaks a normally closed contact. |

| Safety Relay | Monitors the E stop circuit and controls the machine's power. |

| Motor Contactor | Interrupts the power supply to the machine's motor upon command from the safety relay. |

For detailed and reliable E stop wiring diagrams specific to your equipment, always refer to the manufacturer's documentation. This ensures you are working with the most accurate and relevant schematics for your particular setup.