Understanding an Electronic Ignition Coil Wiring Diagram is crucial for anyone working on a vehicle's ignition system. This diagram serves as a roadmap, illustrating how the ignition coil, the heart of the ignition process, receives power and signals to generate the high voltage needed to ignite the fuel-air mixture in your engine. Without a clear grasp of this diagram, troubleshooting ignition issues can become a frustrating and time-consuming endeavor.

The Role of the Electronic Ignition Coil Wiring Diagram

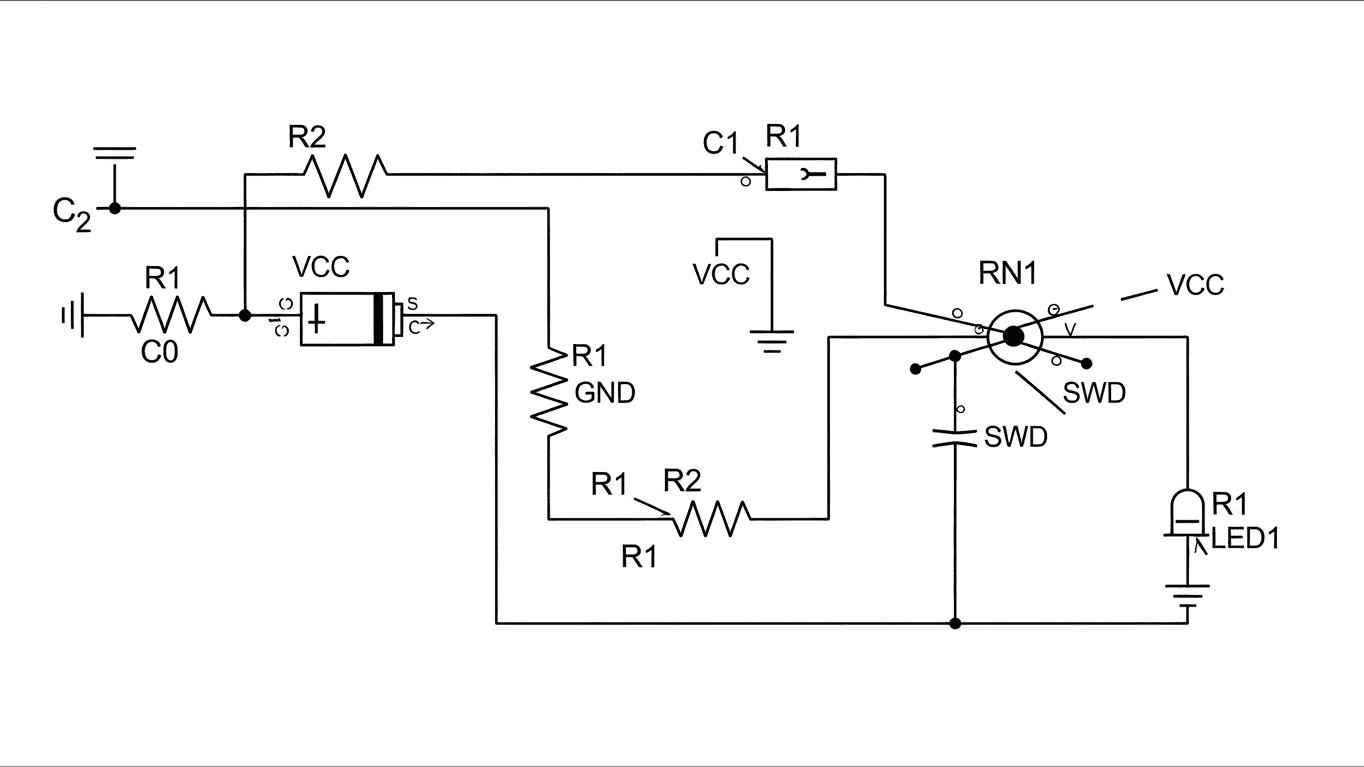

An Electronic Ignition Coil Wiring Diagram is a schematic representation that shows the electrical connections between the ignition coil, the vehicle's battery, the ignition control module (or engine control unit - ECU), and other related components. It details the path of electrical current, the function of each wire, and the proper way to connect them. This diagram is essential for both installation and repair of the ignition system, ensuring that components are connected correctly to achieve optimal performance and prevent damage.

The primary purpose of the ignition coil is to transform the vehicle's low voltage (typically 12 volts) into the extremely high voltage (tens of thousands of volts) required to create a spark across the spark plug gap. The Electronic Ignition Coil Wiring Diagram illustrates how this transformation is facilitated. Key components and their typical connections include:

- Positive (+) Terminal: Receives a constant 12-volt supply from the battery, usually through a fuse or ignition switch.

- Negative (-) Terminal: Receives pulsed signals from the ignition control module, which triggers the coil to fire.

- High-Tension Lead: Connects the ignition coil to the distributor (in older systems) or directly to the spark plug (in modern systems).

The way these connections are made is critical. An incorrect wiring can lead to a no-spark condition, misfires, or even damage to the ignition module or coil itself. The accuracy of the Electronic Ignition Coil Wiring Diagram is of paramount importance for the correct functioning of your vehicle's engine. Whether you are a DIY enthusiast or a professional mechanic, referring to the specific diagram for your vehicle's make, model, and year is non-negotiable. Different ignition systems (e.g., points and condenser, electronic ignition, distributorless ignition systems) will have distinct wiring configurations.

Consider these common scenarios where a wiring diagram is indispensable:

- New Installation: Ensuring all connections are made to the correct terminals for proper operation.

- Troubleshooting: Identifying faulty connections, open circuits, or short circuits that prevent the spark from occurring.

- Component Replacement: Guaranteeing that the new ignition coil is wired precisely as the old one was.

Here's a simplified overview of typical connections you might find in a diagram:

| Component | Connection Point | Purpose |

|---|---|---|

| Battery | Ignition Coil (+) | Provides continuous power |

| Ignition Control Module | Ignition Coil (-) | Provides timing pulses to fire the coil |

| Spark Plug/Distributor | Ignition Coil (High-Tension Output) | Delivers high voltage spark |

When undertaking any work on your ignition system, always consult the specific Electronic Ignition Coil Wiring Diagram provided in your vehicle's service manual or a reliable automotive repair database.

For the most accurate and detailed information specific to your vehicle, please refer to the diagrams found in the section that follows this article.