Navigating the complexities of electrical systems can be daunting, but a clear and comprehensive Emerson Electric Motors Wiring Diagram is an invaluable resource for anyone working with Emerson electric motors. This diagram serves as a visual blueprint, detailing the connections between the motor, its power source, and associated control components. Understanding this diagram is crucial for proper installation, troubleshooting, and maintenance, ensuring safe and efficient operation of your Emerson electric motor.

What is an Emerson Electric Motors Wiring Diagram?

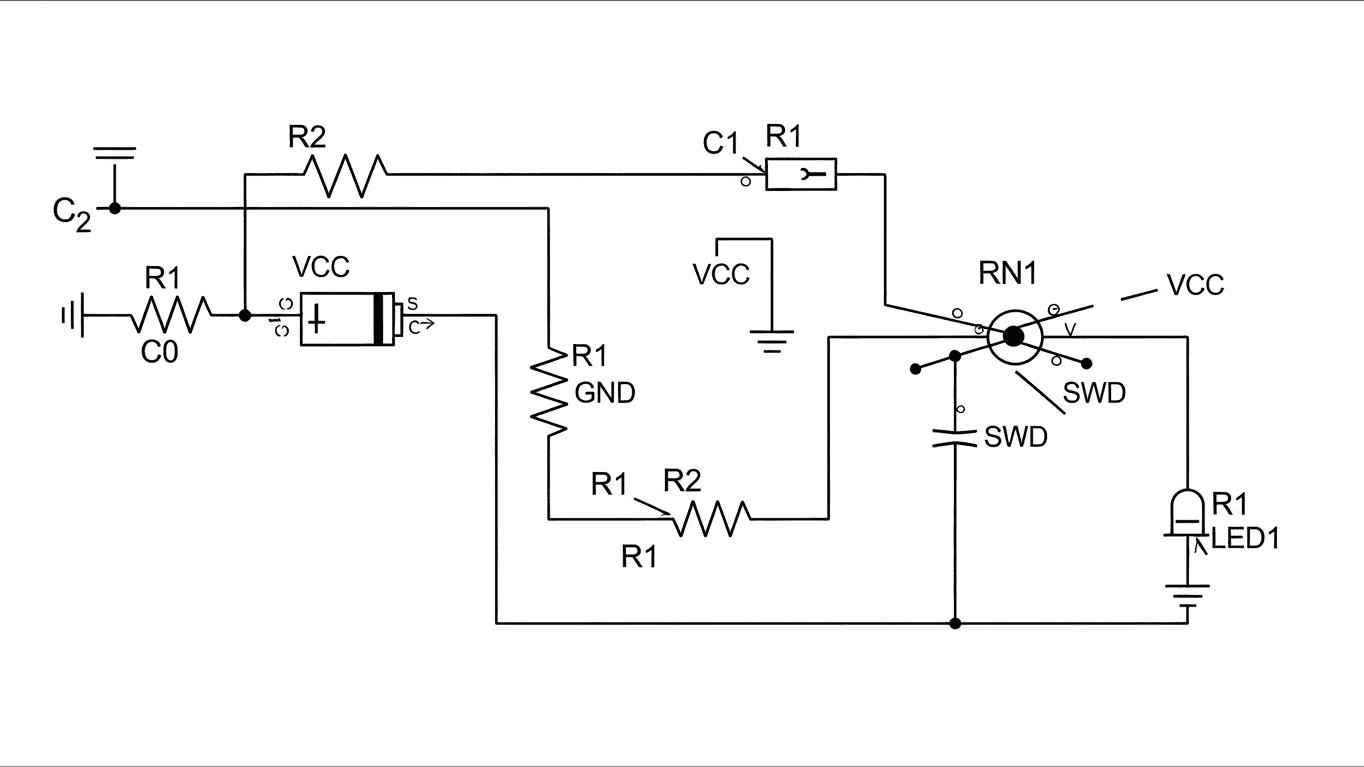

An Emerson Electric Motors Wiring Diagram is a schematic representation that illustrates the electrical pathways and connections within an Emerson electric motor and its associated circuitry. It acts as a language that electricians and technicians use to communicate the intricate details of how the motor receives power, how it's controlled, and how it interacts with other electrical components. These diagrams are not just random lines and symbols; they are standardized representations designed to convey specific information efficiently. Without a proper Emerson Electric Motors Wiring Diagram , attempting to connect or repair a motor can lead to serious damage, safety hazards, and costly downtime.

The primary purpose of an Emerson Electric Motors Wiring Diagram is to provide clear instructions for electrical connections. It typically shows:

- Power input terminals (L1, L2, L3, or single-phase equivalents)

- Motor winding connections (e.g., for different speeds or configurations)

- Grounding points for safety

- Connections to control devices like switches, relays, and contactors

- Wiring for protective devices such as overload relays and fuses

These diagrams are essential for several reasons:

- Installation: Ensures the motor is wired correctly from the start, preventing immediate issues.

- Troubleshooting: Helps identify the root cause of electrical problems by tracing circuits and checking connections.

- Maintenance: Facilitates routine checks and component replacements.

- Safety: Crucial for understanding grounding and overload protection, preventing electrical shocks and fires.

For example, a single-phase capacitor-start motor wiring diagram will look different from a three-phase motor wiring diagram. The complexity of the diagram directly correlates with the motor's capabilities and the control system it's integrated into. Different motor types also require specific diagrams. Here’s a simplified look at common elements found:

| Symbol | Meaning |

|---|---|

| L1, L2, L3 | Line Power Connections |

| T1, T2, T3... | Motor Terminal Designations |

| [ ] | Switch or Contactor |

| O | Overload Relay |

The accuracy and clarity of the Emerson Electric Motors Wiring Diagram are paramount for any electrical work performed on Emerson motors.

When you need to understand the specifics of your Emerson electric motor's electrical setup, always refer to the official documentation provided by Emerson. The detailed schematics within these resources are your most reliable guide.