Understanding an Engine Hour Meter Wiring Diagram is crucial for anyone who needs to accurately track the operating time of their engine. Whether it's for maintenance scheduling, performance analysis, or warranty purposes, a properly wired hour meter ensures reliable data. This article will demystify the "Engine Hour Meter Wiring Diagram" and guide you through its essentials.

What is an Engine Hour Meter Wiring Diagram and How is it Used?

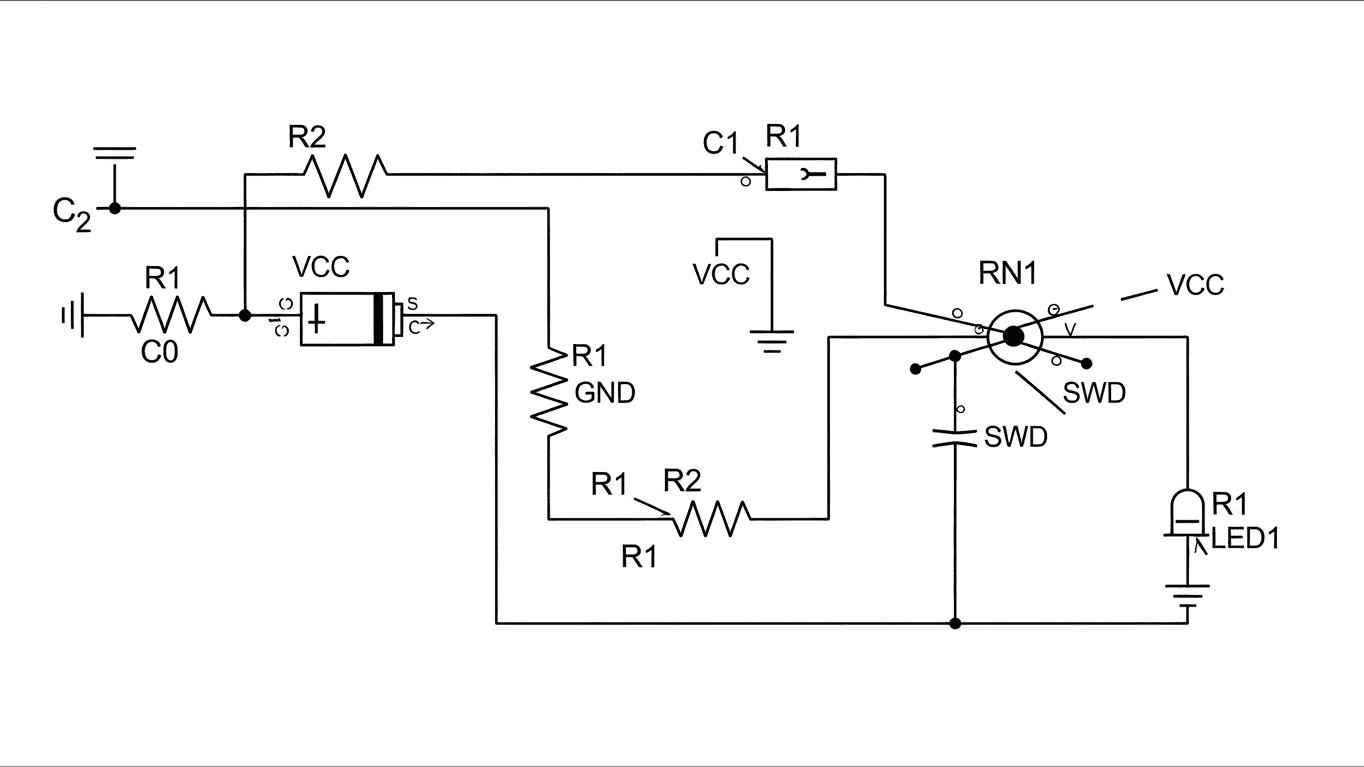

An Engine Hour Meter Wiring Diagram is a schematic illustration that shows how to connect an hour meter to an engine's electrical system. It essentially provides a blueprint, detailing the necessary wires, their connection points, and any required components like fuses or relays. These diagrams are indispensable tools for mechanics, technicians, and even hobbyists working with various types of engines, from small generators and lawnmowers to large industrial machinery and vehicles. By following the diagram, users can ensure the hour meter receives the correct power signal to accurately count the engine's running time.

The primary function of an hour meter is to record the cumulative hours an engine has been in operation. This information is vital for several reasons:

- Preventative Maintenance: Many maintenance schedules are based on engine hours (e.g., oil changes every 500 hours). An accurate meter ensures these intervals are met.

- Performance Monitoring: Tracking hours can help in analyzing fuel efficiency or identifying potential issues that might be related to usage.

- Warranty Tracking: Manufacturers often base warranty coverage on a specific number of operating hours.

- Resale Value: For used equipment, a documented and accurate hour reading significantly impacts its market value.

The importance of a correctly wired hour meter cannot be overstated, as it directly impacts the longevity and efficiency of the engine.

Different types of hour meters exist, and their wiring can vary slightly. However, most diagrams will illustrate connections for at least two main power sources:

- Power Source (Ignition Switched): This is typically a wire that receives power only when the engine's ignition is turned on. This ensures the meter only counts hours when the engine is actually running or about to run.

- Ground: This connects the hour meter to the engine's chassis or a designated ground point, completing the electrical circuit.

For some applications, you might also find diagrams indicating connections for:

| Component | Purpose |

|---|---|

| Fuse | Protects the hour meter and wiring from electrical surges. |

| Relay | Used in some systems to handle higher current loads or to switch power to the meter based on other engine signals. |

Always refer to the specific wiring diagram provided by the hour meter manufacturer or the equipment manual for your particular application.

To successfully install or troubleshoot your engine hour meter, consult the detailed diagrams available in your equipment's service manual or from the hour meter manufacturer. These resources provide the precise information you need for a correct and reliable setup.