Understanding the intricacies of your vehicle's electrical system is crucial for efficient maintenance and troubleshooting. The Fisher Fleet Flex Wiring Diagram serves as a vital blueprint, providing a clear and organized representation of how various electrical components are interconnected within Fisher equipment. Whether you're a seasoned mechanic or a new operator, grasping the information presented in a Fisher Fleet Flex Wiring Diagram can significantly streamline your work.

What is a Fisher Fleet Flex Wiring Diagram and How is it Used?

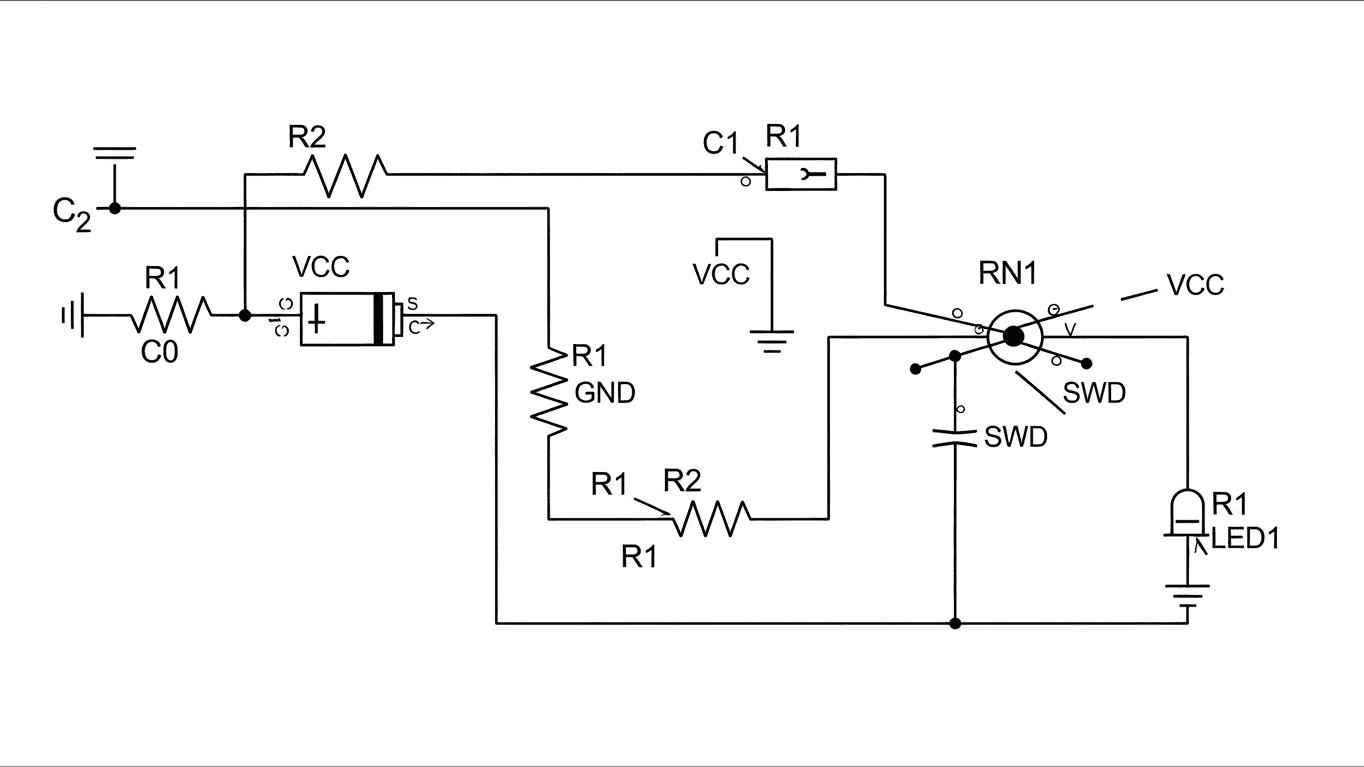

A Fisher Fleet Flex Wiring Diagram is a technical drawing that illustrates the electrical pathways, connections, and components of a Fisher snowplow or salt spreader system designed for fleet applications. These diagrams are indispensable tools for diagnosing electrical issues, performing installations, and ensuring the correct operation of complex systems. They map out everything from the battery and control unit to individual lights, motors, solenoids, and sensors. The ability to accurately interpret and utilize a Fisher Fleet Flex Wiring Diagram is fundamental to maintaining the reliability and functionality of your fleet equipment.

Fleet managers and technicians rely on these diagrams for a multitude of tasks. For instance, when a light fails, the diagram helps pinpoint the exact wire, fuse, or component that might be at fault. When installing new accessories or upgrading existing systems, the diagram guides the proper connections, preventing short circuits and ensuring compatibility. The diagrams often include:

- Wire colors and gauge specifications.

- Component identification symbols.

- Terminal designations.

- Fuse and relay locations.

- Circuit protection methods.

These visual aids are not merely charts; they are comprehensive guides that can save considerable time and expense. A typical Fisher Fleet Flex Wiring Diagram might be structured to show different systems separately, such as the plow control system, the lighting system, and the hydraulic system, allowing for focused troubleshooting. Consider the following breakdown of common elements you might find:

| Component | Purpose | Location on Diagram |

|---|---|---|

| Battery | Power source | Often at the beginning of major circuits |

| Control Unit | Manages plow functions | Central hub for control signals |

| Solenoids | Control fluid flow to hydraulics | Connected to hydraulic pump and cylinders |

| Lights | Visibility and signaling | Grouped by function (headlights, strobes) |

By providing this level of detail, the Fisher Fleet Flex Wiring Diagram empowers users to understand the flow of electricity and how each part contributes to the overall operation of the equipment.

To access the specific Fisher Fleet Flex Wiring Diagram relevant to your equipment, consult the resources provided by Fisher Engineering. These official documents are the most accurate and up-to-date sources for your wiring needs.