Understanding a Flow Switch Wiring Diagram is essential for anyone working with fluid systems. Whether you are installing a new system, troubleshooting an existing one, or simply trying to grasp the intricacies of fluid control, a Flow Switch Wiring Diagram provides the blueprint for how these vital components are connected. This diagram is your roadmap to ensuring your flow switches operate correctly, protecting your equipment and optimizing your processes.

What is a Flow Switch Wiring Diagram and How Are They Used?

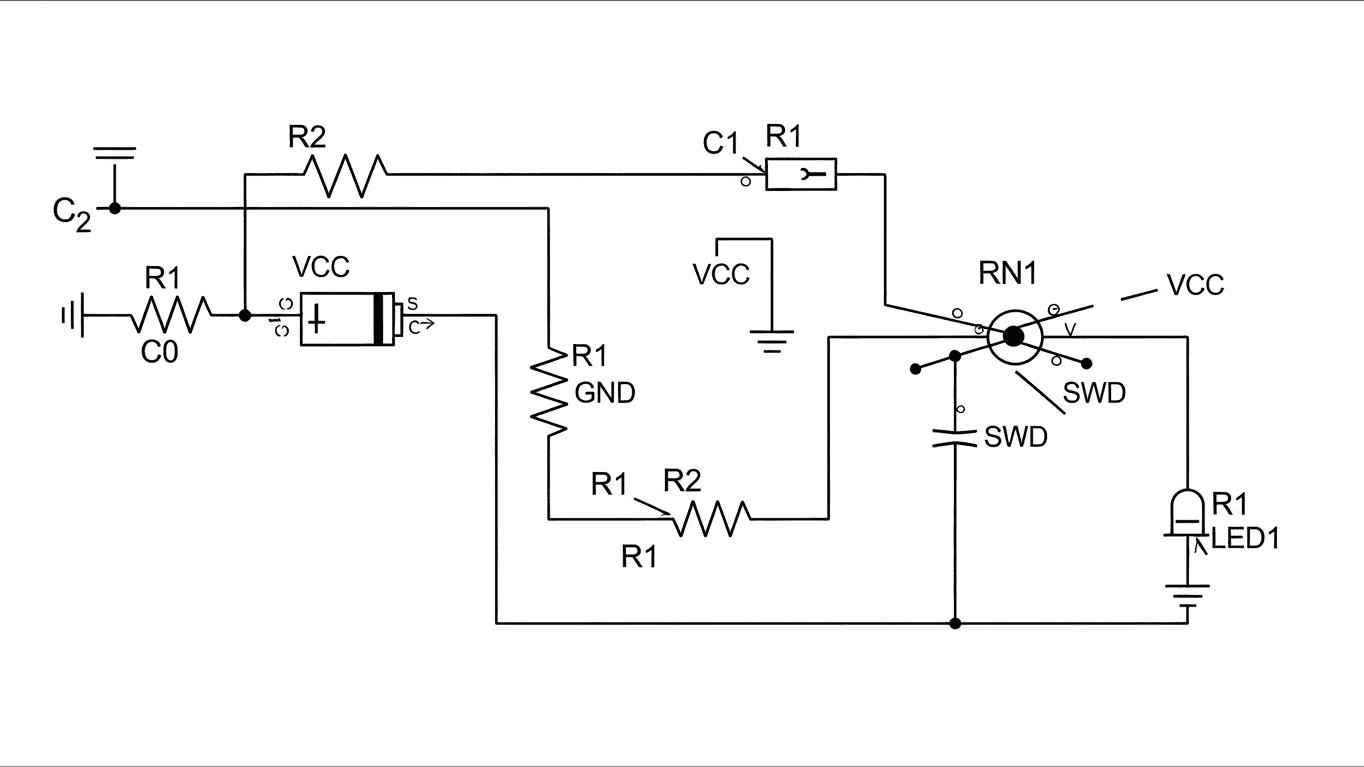

A Flow Switch Wiring Diagram is a schematic representation that illustrates the electrical connections between a flow switch and other components in a system, such as pumps, control panels, alarms, or indicator lights. These diagrams are crucial because flow switches are designed to detect the presence or absence of fluid movement. When fluid flow reaches a predetermined level, the switch will either open or close an electrical circuit, signaling this change to the connected equipment. The proper interpretation and implementation of a Flow Switch Wiring Diagram are paramount to the safe and efficient operation of countless industrial and domestic applications.

The applications for flow switches are diverse and far-reaching. In HVAC systems, they might be used to detect water flow in heating or cooling coils, preventing damage from low flow conditions. In industrial processes, they can monitor the flow of coolants, lubricants, or process chemicals, triggering shutdowns or alarms if flow is interrupted. Even in simple domestic settings, they can be found in washing machines to ensure water is flowing correctly. The diagram serves as a universal language, allowing technicians and engineers to quickly understand:

- The type of flow switch being used (e.g., paddle, thermal dispersion, piston).

- The number of terminals on the flow switch.

- How the flow switch is wired into the control circuit (normally open or normally closed contacts).

- Which other components are being controlled or monitored by the flow switch.

For example, a basic flow switch wiring diagram might show a flow switch connected in series with a pump motor's control relay. When flow is detected, the switch closes, energizing the relay and allowing the pump to run. If flow drops below a set point, the switch opens, de-energizing the relay and stopping the pump. More complex systems might involve multiple flow switches, pressure sensors, and timers, all interconnected as detailed in their respective wiring diagrams. A tabular representation might look like this:

| Component | Connection Point | Function |

|---|---|---|

| Flow Switch | Terminal 1 & 2 | Signal circuit for pump control |

| Pump Control Relay | Coil Terminals | Activates pump motor |

| Indicator Light | Wired in parallel with pump | Shows pump operation |

To effectively understand and implement these connections, it is highly recommended to consult the specific Flow Switch Wiring Diagram provided by the manufacturer for your particular model and application. This will ensure accurate and safe installation, preventing potential system failures or hazards.