Understanding the Ford 2 Wire Crank Sensor Wiring Diagram is crucial for anyone looking to diagnose or repair their vehicle's ignition or fuel system. This diagram provides a visual guide to how the crankshaft position sensor, a vital component, connects to the vehicle's engine control module (ECM). Proper knowledge of this Ford 2 Wire Crank Sensor Wiring Diagram can save you time and money when troubleshooting engine performance issues.

The Role of the Ford 2 Wire Crank Sensor Wiring Diagram

The crankshaft position sensor, often abbreviated as CKP sensor, plays a fundamental role in modern engine operation. It tells the engine's computer, the ECM, the exact rotational speed and position of the crankshaft. This information is critical for several reasons. Without an accurate signal from the CKP sensor, the ECM cannot properly time the ignition spark or the fuel injectors. This is why a correct Ford 2 Wire Crank Sensor Wiring Diagram is so important for technicians and DIY enthusiasts alike.

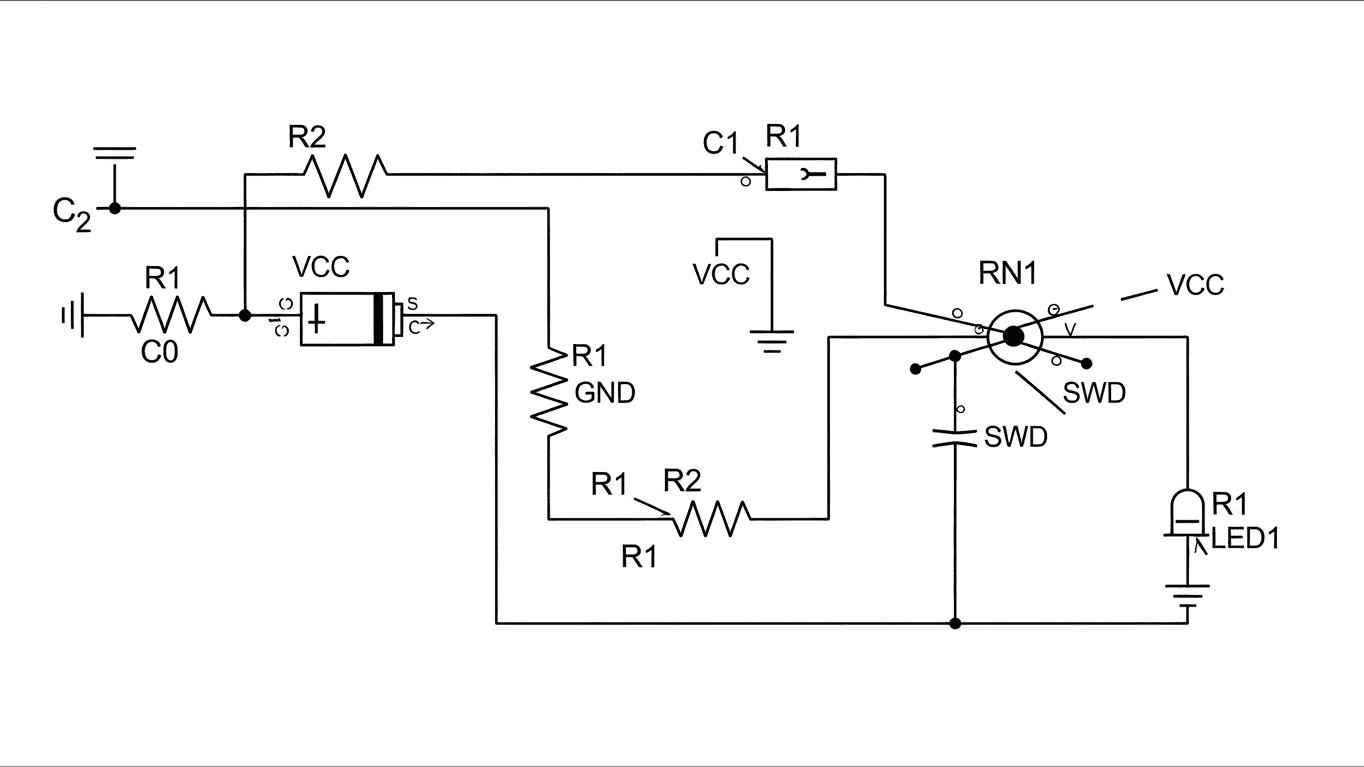

A typical Ford 2 Wire Crank Sensor Wiring Diagram will show two primary wires: one that carries the signal to the ECM and another that serves as a ground. The sensor itself generates a signal, usually an AC voltage, as a metal reluctor wheel attached to the crankshaft passes by its magnetic tip. The frequency and pattern of this signal are what the ECM interprets to determine engine speed and position. Here's a breakdown of what you'll commonly find:

- Signal Wire: This wire transmits the voltage pulse generated by the sensor to the ECM.

- Ground Wire: This wire provides a return path for the electrical current, completing the circuit.

The importance of a functional crankshaft position sensor cannot be overstated. If the wiring is damaged, loose, or corroded, the ECM will not receive the necessary information, leading to a no-start condition, rough idling, stalling, or poor fuel economy. A clear understanding of the Ford 2 Wire Crank Sensor Wiring Diagram allows for systematic troubleshooting. You can use a multimeter to check for continuity on the wires and ensure proper voltage is being sent and received. In some cases, the sensor itself may fail, but a faulty wire or connection is often the culprit, and the wiring diagram is your roadmap to finding it. Let's look at a simplified representation of the circuit:

| Component | Wire Color (Typical) | Function |

|---|---|---|

| Crankshaft Position Sensor | Wire 1 (e.g., Yellow) | Signal Output |

| Crankshaft Position Sensor | Wire 2 (e.g., Black/White) | Ground |

| Engine Control Module (ECM) | Relevant Pin(s) | Receives Signal, Provides Ground |

If you are facing issues with your Ford's engine and suspect a problem with the crankshaft position sensor or its wiring, the specific Ford 2 Wire Crank Sensor Wiring Diagram for your vehicle model is an indispensable tool. It will show you the exact wire colors, their routing, and the pins they connect to on the ECM. This level of detail is essential for accurate diagnosis and repair.

To ensure you're working with the most accurate information, please refer to the detailed Ford 2 Wire Crank Sensor Wiring Diagram provided in the subsequent section. This resource will give you the precise specifications needed to get your Ford back on the road.