Understanding an Emergency Stop Wiring Diagram is vital for ensuring safety in any environment where machinery operates. This diagram acts as a blueprint, detailing how emergency stop buttons are connected to shut down equipment quickly and effectively in hazardous situations. A properly understood Emergency Stop Wiring Diagram can prevent serious accidents.

The Fundamentals of Emergency Stop Wiring Diagrams

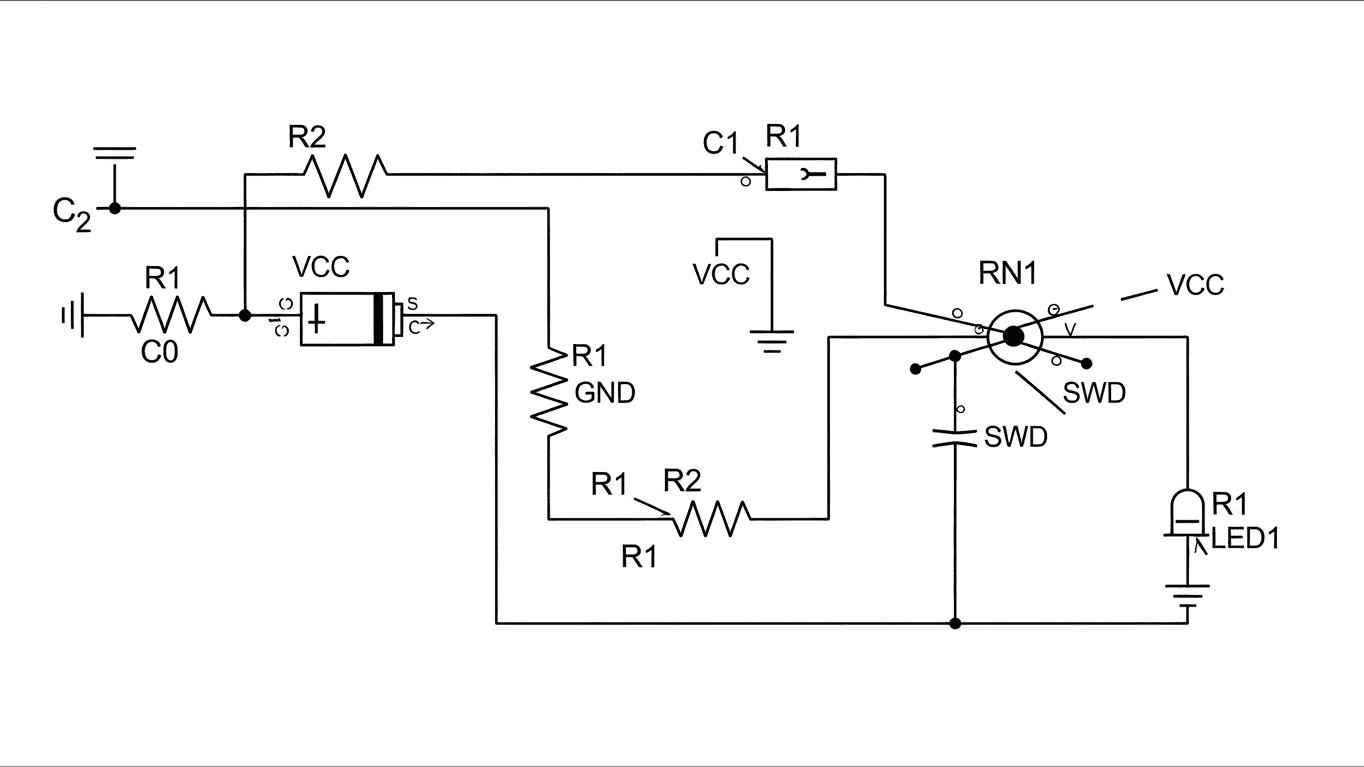

An Emergency Stop Wiring Diagram is a visual representation that illustrates the electrical connections for emergency stop (E-stop) circuits. These circuits are designed to be fail-safe, meaning they rely on components and connections that, if disrupted, will lead to a safe state – typically, the deactivation of machinery. The primary purpose of an E-stop system is to allow immediate cessation of operation when a person or object is in danger. This is achieved through dedicated E-stop buttons strategically placed around the machinery.

The functionality of an Emergency Stop Wiring Diagram relies on specific electrical principles. Most E-stop circuits employ a series configuration where the contacts of each E-stop button are wired in a way that if any button is activated (pressed), it breaks the circuit. This break in the circuit then signals a control relay or safety contactor to de-energize the power to the machine's motor or other operational components. The importance of a properly designed and wired Emergency Stop Wiring Diagram cannot be overstated , as it directly impacts the ability to respond to emergencies and protect personnel.

When examining an Emergency Stop Wiring Diagram, you'll often encounter several key components and configurations:

- E-stop Buttons: These are the physical devices activated by a user. They typically have normally closed (NC) contacts that open when pressed.

- Safety Relays/Contactors: These devices monitor the E-stop circuit and are responsible for cutting power to the machinery. They often have redundant contacts for increased reliability.

- Wiring: The diagram shows the path of the electrical current, ensuring that the E-stop circuit is isolated from the main power control of the machine.

The diagram might illustrate different wiring strategies:

- Direct Wiring: Where E-stop buttons directly control a contactor.

- Safety Relay Integration: A more common and robust method, where E-stop buttons feed into a dedicated safety relay, which then controls the main contactor.

Here's a simplified breakdown of a common E-stop circuit:

| Component | Function | Connection Type |

| E-Stop Button (NC) | Interrupts circuit when pressed | Series |

| Safety Relay | Monitors E-stop circuit, controls output | Receives signal from buttons, controls contactor |

| Motor Contactor | De-energizes motor | Controlled by safety relay |

To truly grasp the intricacies and ensure your safety systems are implemented correctly, it is highly recommended that you consult a detailed and authoritative Emergency Stop Wiring Diagram relevant to your specific equipment. Please refer to the comprehensive documentation provided with your machinery for the most accurate and applicable schematics.